93 Carbed 302 T5 DIY no JB Weld or Duct Tape

#101

I hate those huge **** distys, might as well use a magneto if you want something so honking huge under yer hood.

Car looks like crap due to peeling clearcoat but it looks awesome to me with the hood down:

What a sleeper!

I asked about the carb because other posts led me to believe you'd HAVE to have a scoop for a 302 in a Miata.

Guess that is not true for ALL of them, is it?

Didn't get as much as I wanted done but the drivetrain is completely installed and appears to turn freely with no abnormal noises.

Need to update my signature.

Need to update my signature.

Good job, I like it a lot.

#102

Will Do. Thanks!

#103

I have worked very hard on this project so I would be able to enter the 2014 Grass Roots Challenge. I should have the car finished in time but I would not be able to do any testing, tuning, or body work. Driving 500 miles to break down in the competition is something I feel is not even remotely sensible.

Next year, I'm not going to just enter it, I'm going to WIN it!

Nov 2nd will be the Miata's first autocross race. Can't wait.

Thanks to everyone for your support.

Next year, I'm not going to just enter it, I'm going to WIN it!

Nov 2nd will be the Miata's first autocross race. Can't wait.

Thanks to everyone for your support.

#104

If I could be so bold to make a suggestion... When time started getting tight on you I thought if it was me I think I would focus on a different direction for the event. Seems to me the first time out at an event like this learning the ropes and having fun in more important than winning. I can't think of anything that would spoil it faster than a major break down anytime on the trip.

In discussing it with my son we concluded it would be better to make the trip in any car that is reliable and sport minded rather than building a car from the ground up the first time out. Seeing the event first hand and experiencing it would be the best back ground possible for building a purpose built car for it.

For what it's worth we decided a 2001 to 2005 2 door 5 speed caviler was the car for us. Good drive train in that one and tons of cheap suspension options and easy to sell after words. No word yet on the ideal car for the next year as there are still too many options...

If you have a car laying around that is worth less than 2 grand and can afford the trip it might be worth checking it out this year in preparation to win next year.

In discussing it with my son we concluded it would be better to make the trip in any car that is reliable and sport minded rather than building a car from the ground up the first time out. Seeing the event first hand and experiencing it would be the best back ground possible for building a purpose built car for it.

For what it's worth we decided a 2001 to 2005 2 door 5 speed caviler was the car for us. Good drive train in that one and tons of cheap suspension options and easy to sell after words. No word yet on the ideal car for the next year as there are still too many options...

If you have a car laying around that is worth less than 2 grand and can afford the trip it might be worth checking it out this year in preparation to win next year.

#105

Jim,

Your opinion is highly valued and I totally get where you are coming from.

I am highly competitive and have been drag racing for several years now. In all that time I have had two bad experiences that I never want to repeat:

1 - Drove an hour with car on trailer. Unloaded car and ECM was idle searching like a big dog. Ran a couple of very slow runs and put it back on the trailer.

2 - Showed up at the track with my stock Honda Del Sol and was literally the slowest car at the track. Mopeds' were lining up to take my lunch money!

Given the present state of my car, one or both of the aforementioned would have happened which would have made for a very miserable experience considering the amount of work I have put into the car.

I really should go but I don't have a cheap (reliable) car that would be worth entering. I was thinking that I could do the run for fun with my 500 whp Mustang or better yet, my son's Focus ST. Unfortunately, one is only good in a straight line the other only good in the curves. The issue is that it would be expensive and I can get more practice in at the local drag strip and the local autox races.

I think the Cavalier would be good car. I thought a Probe GT/MX6 GT (turbo) would be good too. Just about any turbo car would be good with enough boost.

Your opinion is highly valued and I totally get where you are coming from.

I am highly competitive and have been drag racing for several years now. In all that time I have had two bad experiences that I never want to repeat:

1 - Drove an hour with car on trailer. Unloaded car and ECM was idle searching like a big dog. Ran a couple of very slow runs and put it back on the trailer.

2 - Showed up at the track with my stock Honda Del Sol and was literally the slowest car at the track. Mopeds' were lining up to take my lunch money!

Given the present state of my car, one or both of the aforementioned would have happened which would have made for a very miserable experience considering the amount of work I have put into the car.

I really should go but I don't have a cheap (reliable) car that would be worth entering. I was thinking that I could do the run for fun with my 500 whp Mustang or better yet, my son's Focus ST. Unfortunately, one is only good in a straight line the other only good in the curves. The issue is that it would be expensive and I can get more practice in at the local drag strip and the local autox races.

I think the Cavalier would be good car. I thought a Probe GT/MX6 GT (turbo) would be good too. Just about any turbo car would be good with enough boost.

#106

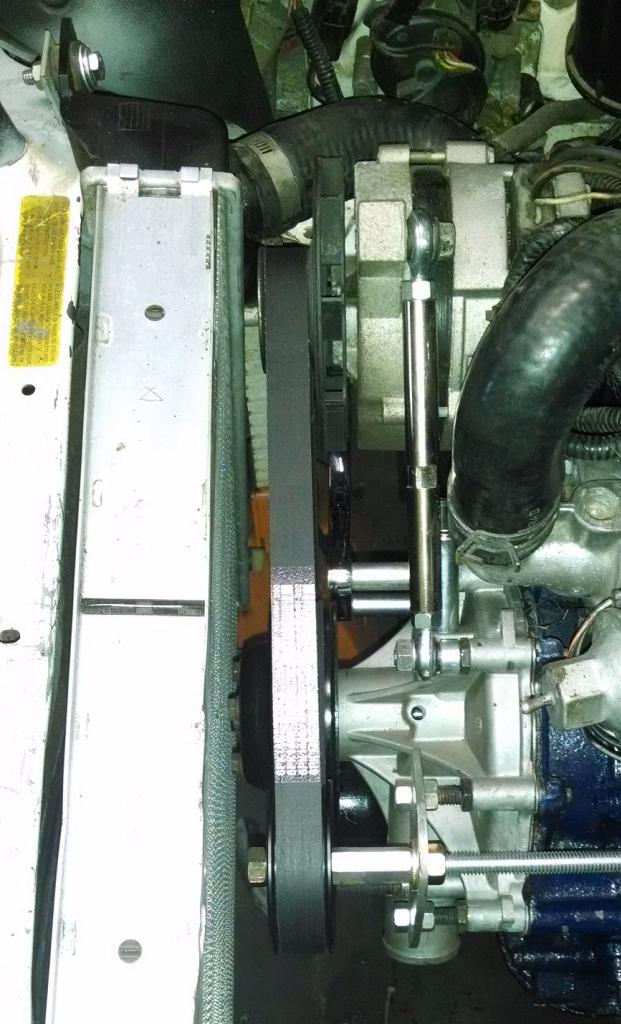

Finally got the accessory drive completed. This has been a royal PITA since you can't just go buy a bracket & pulley that will bolt on and work from a junk yard. I wanted to try the Miata sans PS first since the manual steering represents a significant weight (and complexity) savings.

I have seen images of March Performance's setup but didn't have that in my budget. So I bought the $40 billet (eBay) brackets for the alternator and made a bracket for an idler pulley as shown below. The pulley slides onto one of the unions that has been machined down (grinder) to fit the inner diameter of the pulley bearing and cut to length (bearing width). Washers and nuts secure it on the threaded rod. The steel plate prevents the threaded rod from flexing due to side loading from the serpentine belt.

Here is my parts list:

* 10" of 7/16 threaded rod - bolts into the block and is secured with a nut

* Several 7/16 nuts and washers

* 4 nuts to fit the water pump studs (standoffs for steel plate)

* 2 of the unions for threaded rods which are basically 1 3/4" long nuts

* Dayco 89009 idler/tensioner pulley (Advance Auto)

* Piece of steel plate - cut and drilled by using a cardboard template

Once complete, it is extremely rigid and the union sandwiched between the plate and the pulley effectively increased the diameter of the threaded rod (less flexing). Tension is adjusted with the eBay kit's adjuster. If you have issues with the belt walking, use washers to adjust the location of the pulley relative to the other pulleys (front to rear).

Hope this helps prevent someone else from spending hours looking for a solution that really doesn't exist. Let me know if you have any questions.

NOTE: Everything on the passenger side of the water pump is from the eBay kit.

No Power Steering - Because Racecar! lol

I have seen images of March Performance's setup but didn't have that in my budget. So I bought the $40 billet (eBay) brackets for the alternator and made a bracket for an idler pulley as shown below. The pulley slides onto one of the unions that has been machined down (grinder) to fit the inner diameter of the pulley bearing and cut to length (bearing width). Washers and nuts secure it on the threaded rod. The steel plate prevents the threaded rod from flexing due to side loading from the serpentine belt.

Here is my parts list:

* 10" of 7/16 threaded rod - bolts into the block and is secured with a nut

* Several 7/16 nuts and washers

* 4 nuts to fit the water pump studs (standoffs for steel plate)

* 2 of the unions for threaded rods which are basically 1 3/4" long nuts

* Dayco 89009 idler/tensioner pulley (Advance Auto)

* Piece of steel plate - cut and drilled by using a cardboard template

Once complete, it is extremely rigid and the union sandwiched between the plate and the pulley effectively increased the diameter of the threaded rod (less flexing). Tension is adjusted with the eBay kit's adjuster. If you have issues with the belt walking, use washers to adjust the location of the pulley relative to the other pulleys (front to rear).

Hope this helps prevent someone else from spending hours looking for a solution that really doesn't exist. Let me know if you have any questions.

NOTE: Everything on the passenger side of the water pump is from the eBay kit.

No Power Steering - Because Racecar! lol

Last edited by Jack Sprat; 10-05-2014 at 07:52 PM.

#107

Wow, this looks really great and it's a budget solution to boot.

I am planning a similar setup, i.e., also trying the manual steering rack first, mainly because I'm running a Holley Systemax manifold that, even after milling to match the shaved AFR heads, will be taller than stock. The manual rack allows mounting the engine just a bit lower, hopefully under the hood. Hope I like the manual steering.

I am also eliminating the smog pump but retaining air conditioning. I bought a March Performance pulley setup intended for this exact configuration, but it's a crap shoot as to whether the components positioning will work in the Miata engine bay. I haven't been able to find any info on the relative mounting and positioning of the alternator and A/C compressor relative to a stock '89 - '93 Mustang. Obviously the March setup will fit in the Fox body cars, but that's no guarantee of avoiding interference in the Miata chassis.

Anybody ever use a March setup on the Ford V8?

I am planning a similar setup, i.e., also trying the manual steering rack first, mainly because I'm running a Holley Systemax manifold that, even after milling to match the shaved AFR heads, will be taller than stock. The manual rack allows mounting the engine just a bit lower, hopefully under the hood. Hope I like the manual steering.

I am also eliminating the smog pump but retaining air conditioning. I bought a March Performance pulley setup intended for this exact configuration, but it's a crap shoot as to whether the components positioning will work in the Miata engine bay. I haven't been able to find any info on the relative mounting and positioning of the alternator and A/C compressor relative to a stock '89 - '93 Mustang. Obviously the March setup will fit in the Fox body cars, but that's no guarantee of avoiding interference in the Miata chassis.

Anybody ever use a March setup on the Ford V8?

#108

Thanks.

I hope the manual rack works good as well. I read that on Mustangs it is only annoying when parking and that manual rack ratios are pretty good so you can even parallel park without much trouble - unless you have Spongebob arms. On top of the weight savings, an added benefit is that you get more of the road feel.

I hope the manual rack works good as well. I read that on Mustangs it is only annoying when parking and that manual rack ratios are pretty good so you can even parallel park without much trouble - unless you have Spongebob arms. On top of the weight savings, an added benefit is that you get more of the road feel.

#109

Thanks.

I hope the manual rack works good as well. I read that on Mustangs it is only annoying when parking and that manual rack ratios are pretty good so you can even parallel park without much trouble - unless you have Spongebob arms. On top of the weight savings, an added benefit is that you get more of the road feel.

I hope the manual rack works good as well. I read that on Mustangs it is only annoying when parking and that manual rack ratios are pretty good so you can even parallel park without much trouble - unless you have Spongebob arms. On top of the weight savings, an added benefit is that you get more of the road feel.

#110

#112

I noticed that today is the 9 month anniversary from my first post. I can't believe it has taken me this long but today was a significant milestone. Unlike all previous days, the car will start and run as long as I want it to instead of leaking gas from the carb and dying out. I decided to rebuild the old Holley and so far, it is working perfectly.

The serpentine drive system that I built is also working perfectly.

The slave cylinder will not bleed so I think the master is bypassing. Will replace this weekend.

Today I got the exhaust tubing and two mandrel bent pipes to come off the headers. I will bend the rest myself - hope to get it done this weekend too since I can't stand the open headers.

Lots of little stuff left to do but I'm have committed the car to an autox race Nov 1st & 2nd. Wish me luck.

The serpentine drive system that I built is also working perfectly.

The slave cylinder will not bleed so I think the master is bypassing. Will replace this weekend.

Today I got the exhaust tubing and two mandrel bent pipes to come off the headers. I will bend the rest myself - hope to get it done this weekend too since I can't stand the open headers.

Lots of little stuff left to do but I'm have committed the car to an autox race Nov 1st & 2nd. Wish me luck.

Last edited by Jack Sprat; 10-24-2014 at 08:23 PM.

#113

Busy Weekend!

The clutch master was toast. New one worked like a charm. Removed the rubber bump stop and lengthened the rod to provide the maximum amount of stroke for the Miata factory slave.

Made adjustable rod (bold) for slave cyl. It's a PITA to adjust but I'm sure it will come in handy in the future.

Rebuilt the Holley (no leaks so far)

Car starts and runs off ignition switch!

1/2 of the exhaust is done

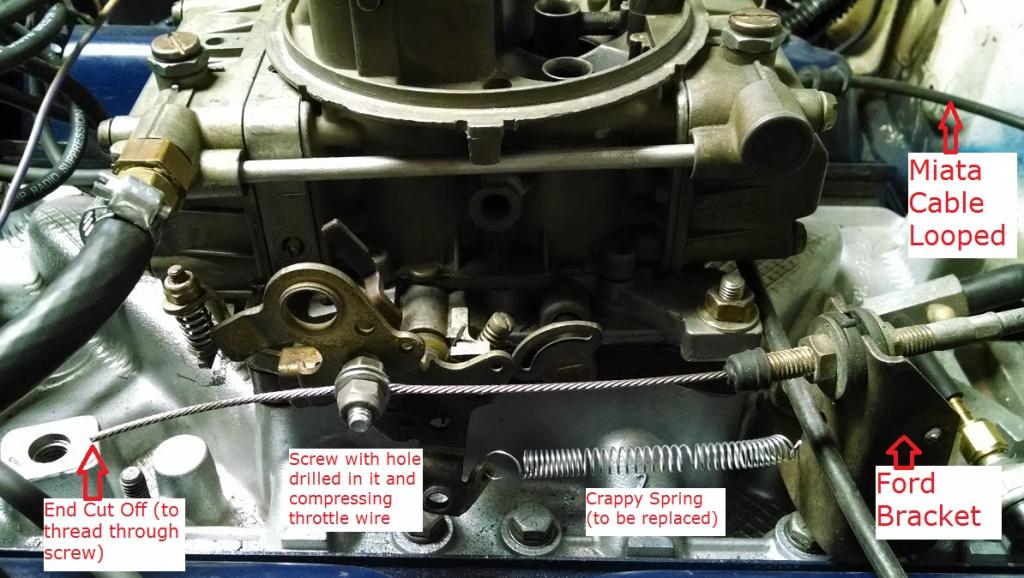

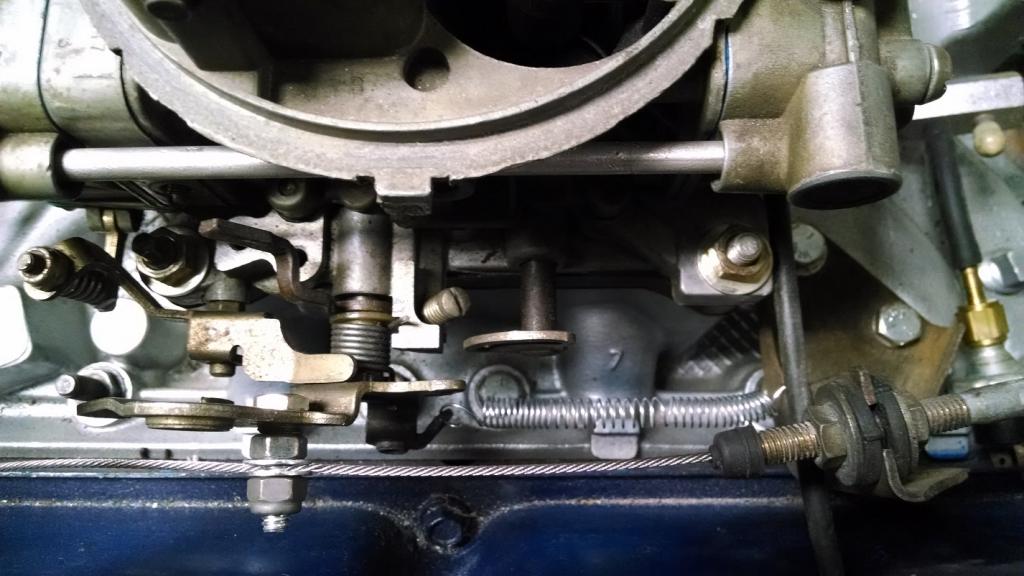

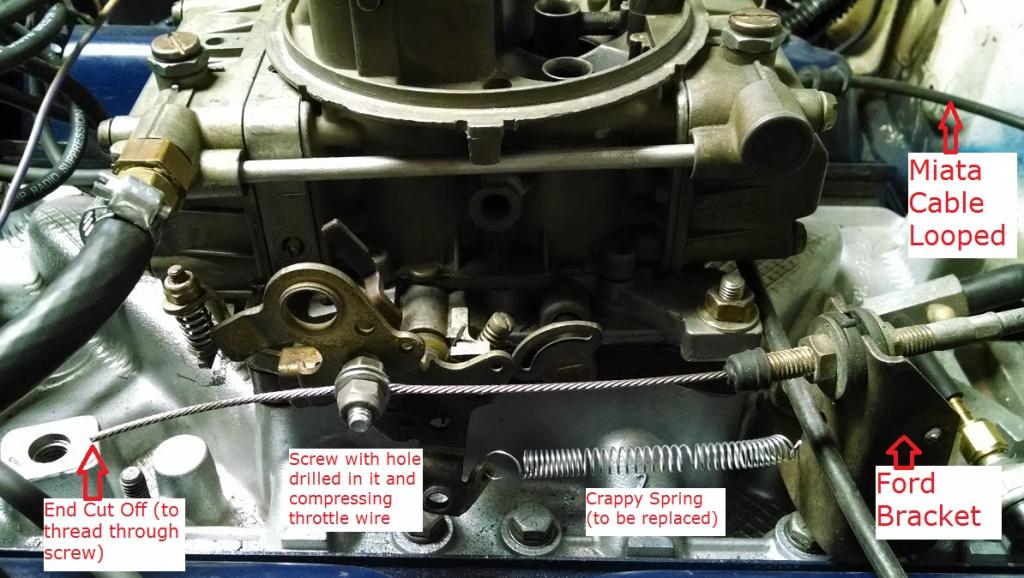

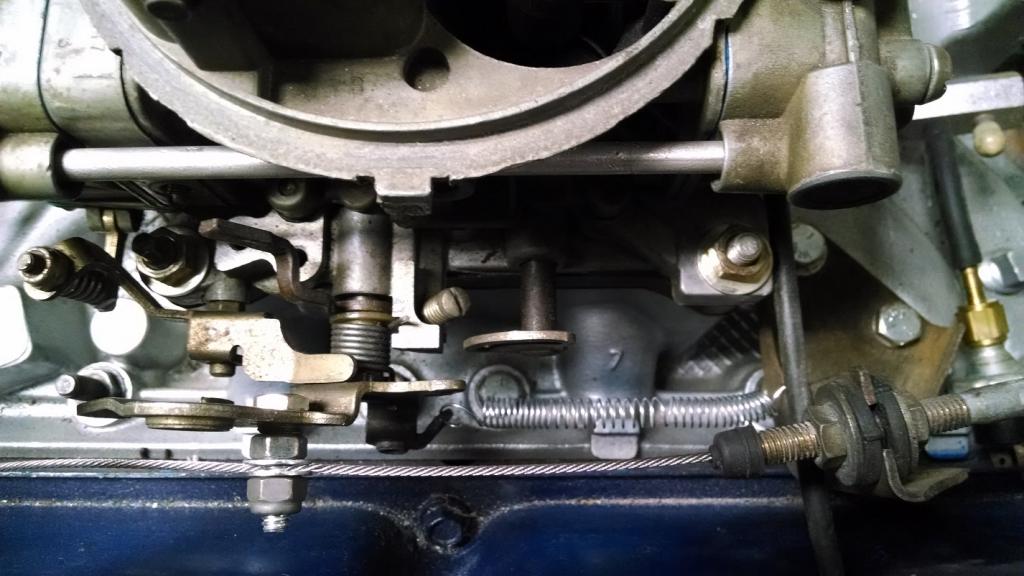

Throttle is working see attached pictures (very little modding)

NOTE: make sure the screw is loose enough to rotate when the linkage moves.

I'm signed up for an autocross this coming weekend, it's gonna be down to the wire to get the car finished.

The clutch master was toast. New one worked like a charm. Removed the rubber bump stop and lengthened the rod to provide the maximum amount of stroke for the Miata factory slave.

Made adjustable rod (bold) for slave cyl. It's a PITA to adjust but I'm sure it will come in handy in the future.

Rebuilt the Holley (no leaks so far)

Car starts and runs off ignition switch!

1/2 of the exhaust is done

Throttle is working see attached pictures (very little modding)

NOTE: make sure the screw is loose enough to rotate when the linkage moves.

I'm signed up for an autocross this coming weekend, it's gonna be down to the wire to get the car finished.

Last edited by Jack Sprat; 10-26-2014 at 09:44 PM.

#114

Took a vacation day today to make some progress on the car. Made a ton of progress, ended converting the car from a jackstand racer to a yard racer. The clutch needs some adjusting but I was able to drive it out of the garage.

#117

Thanks Sunshine Guy. Yeah, it painted the road pretty well even with the ET streets.

I had to lengthen the clutch pedal to MS rod by about 1/2 inch. It's a pretty easy mod. I am amazed that I have kept the Miata master and slave. I shortened the metal line to drop it down towards the middle of the engine but otherwise the plumbing is the same.

I had to lengthen the clutch pedal to MS rod by about 1/2 inch. It's a pretty easy mod. I am amazed that I have kept the Miata master and slave. I shortened the metal line to drop it down towards the middle of the engine but otherwise the plumbing is the same.

#118

If you have gotten the clutch to fully disengage with no drag when depressed, and no slipping when released, you have overcome one of the most common challenges in this swap. Nearly everyone ends up spending a lot of time, effort and a little experimentation to get this right. The short travel provided by the diminutive Miata clutch pedal seems to leave no room for error.

#119

I saw a few pics but didn't read about all the problems. I just may have gotten lucky then.

I have the slave cylinder mounted as far inward towards the center of the trans as possible. By moving the rod up the fulcrum, the rod travel needed to disengage the clutch is as small of a distance as possible.

I made slave cylinder push rod from a grade 8 bolt using the threads and a locking nut for adjustment. I adjusted it so that it had a tiny amount of play.

Then I noticed that the master had a lot of play so I lengthened the shock rod about 1/2 - 3/4 inch. I adjusted it back until the there was a tiny amount of play as well.

The pedal operation is really good and the pedal force is not bad at all. I'll take luck over skill any day!

I have the slave cylinder mounted as far inward towards the center of the trans as possible. By moving the rod up the fulcrum, the rod travel needed to disengage the clutch is as small of a distance as possible.

I made slave cylinder push rod from a grade 8 bolt using the threads and a locking nut for adjustment. I adjusted it so that it had a tiny amount of play.

Then I noticed that the master had a lot of play so I lengthened the shock rod about 1/2 - 3/4 inch. I adjusted it back until the there was a tiny amount of play as well.

The pedal operation is really good and the pedal force is not bad at all. I'll take luck over skill any day!

Last edited by Jack Sprat; 11-01-2014 at 09:35 PM.

#120

Ha ha outstanding! I had to go grab my son and show him the videos as soon as I saw them. Proof it doesn't take a truck load of cash to build a V8 Miata!!  It sounds wonderful and I'm just thrilled for you.

It sounds wonderful and I'm just thrilled for you.

So did you run the autox? Any updates? Any more videos??

It sounds wonderful and I'm just thrilled for you.

It sounds wonderful and I'm just thrilled for you. So did you run the autox? Any updates? Any more videos??

Last edited by charchri4; 11-06-2014 at 08:22 PM.

#121

Don't think I could have made it happened with you Jim as well as others on the board. There were times that I stalled because I was overthinking it. You pointed out how obvious things were when I couldn't see the forest for the trees.

I think it sounds great too. Needs more power. It currently has crappy heads on it but I have heard that the heads respond well to porting.

The most amazing thing is that it drives perfectly. It doesn't even need an alignment. I planned to do all the mods to front subframe with it in the car so nothing could shift or distort from the cutting/welding. The plan worked.

I didn't make the autox with the Miata because the tow vehicle was having problems. lol I'm taking it to the drag strip Sunday (I hope) to get some baseline runs in. In a week or two or three, I'll autox it.

I think it sounds great too. Needs more power. It currently has crappy heads on it but I have heard that the heads respond well to porting.

The most amazing thing is that it drives perfectly. It doesn't even need an alignment. I planned to do all the mods to front subframe with it in the car so nothing could shift or distort from the cutting/welding. The plan worked.

I didn't make the autox with the Miata because the tow vehicle was having problems. lol I'm taking it to the drag strip Sunday (I hope) to get some baseline runs in. In a week or two or three, I'll autox it.

#122

I do some photography, so I know it is totally possible that the appearance of misalignment may be totally caused by the angle of the shot, the relative distance of the two objects from the lens, as well as actual optical distortion. But in the spirit of trying to be helpful, thought I should mention it anyway.

The way your idler is designed, it would be wonderfully easy to adjust.

#123

I hope the manual rack works good as well. I read that on Mustangs it is only annoying when parking and that manual rack ratios are pretty good so you can even parallel park without much trouble - unless you have Spongebob arms. On top of the weight savings, an added benefit is that you get more of the road feel.

Driving down the road the steering has a very firm, solid, on-center feel that gives a nice sense of control. The other conversion car I'm working on already has a power rack in it, and a while back I purchased a new, manual rack. So I have my choice, and I'm pretty sure I'll go with the manual rack as it's worth it to me to get a bit more clearance under the hood.

#124

In this photo, it appears the idler pulley might be a bit further rearward than the alternator pulley. It would be easy to put a straight edge across both pulley faces to check it.

I do some photography, so I know it is totally possible that the appearance of misalignment may be totally caused by the angle of the shot, the relative distance of the two objects from the lens, as well as actual optical distortion. But in the spirit of trying to be helpful, thought I should mention it anyway.

The way your idler is designed, it would be wonderfully easy to adjust.

I do some photography, so I know it is totally possible that the appearance of misalignment may be totally caused by the angle of the shot, the relative distance of the two objects from the lens, as well as actual optical distortion. But in the spirit of trying to be helpful, thought I should mention it anyway.

The way your idler is designed, it would be wonderfully easy to adjust.

To me, the threaded rod made the most since for ease of adjustment and not having to spend time on a mill (don't have) or tapping (no s.a.e. dies). I'm really happy with the setup.

#125

A little update on driveability:

I made ALL (cutting & welding) of the modifications to the front subframe with it in the car. I did not remove the rack or tie rods while doing the mods. This was much harder to work on BUT the reward was a car that drives straight and true, with no bump steer or wander even with the larger tires. This was my plan from the start, If everything stays rigidly mounted it will be much less likely to warp, twist, shrink or expand from my mods. I welded no more than 2 inches continuously to prevent warping as well - learned that from Muscle Car (car show).

Like Sunshine said, the manual steering is not a problem. In fact, I'm going to put a smaller steering wheel on it so I can steer a little quicker around the autox.

I am really happy with the results and I am not a fabricator or a welder. I have an angle grinder, sawzall, and a stick welder. It is a great project with determination and some prodding from the guys on here I feel most anyone with some skills can make a cool car.

I made ALL (cutting & welding) of the modifications to the front subframe with it in the car. I did not remove the rack or tie rods while doing the mods. This was much harder to work on BUT the reward was a car that drives straight and true, with no bump steer or wander even with the larger tires. This was my plan from the start, If everything stays rigidly mounted it will be much less likely to warp, twist, shrink or expand from my mods. I welded no more than 2 inches continuously to prevent warping as well - learned that from Muscle Car (car show).

Like Sunshine said, the manual steering is not a problem. In fact, I'm going to put a smaller steering wheel on it so I can steer a little quicker around the autox.

I am really happy with the results and I am not a fabricator or a welder. I have an angle grinder, sawzall, and a stick welder. It is a great project with determination and some prodding from the guys on here I feel most anyone with some skills can make a cool car.