Adams LS1 NB Build

#27

V8 Miata Follower

Thread Starter

I got my accelerometer working with the JBPerf board. Right now I'm just communicating with the board directly (rather than over CAN through MS3), so I'm only displaying the raw ADC values. I think I can get over 8 ADC's with making a conditioning circuit, so I'll run the 3 axis. I've also decided to add a coolant pressure sensor. This can help detect knock (high cylinder pressure causes a very quick head float pumping pressure to the system), and can save an engine on track. Heads warp when the engine is hot and there is air in the passages, so a blown hose on track could warp the head before the coolant temperature sensor indicates an issue.

Not sure if we can embed YouTube videos on this page..

https://www.youtube.com/watch?v=f34PL53LGF8

Not sure if we can embed YouTube videos on this page..

https://www.youtube.com/watch?v=f34PL53LGF8

#28

V8 Miata Follower

Thread Starter

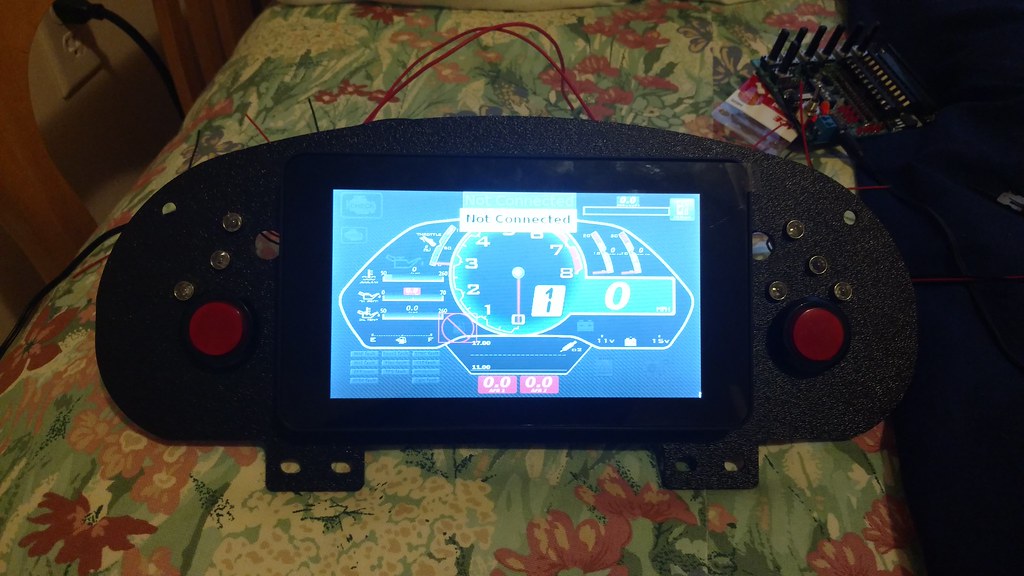

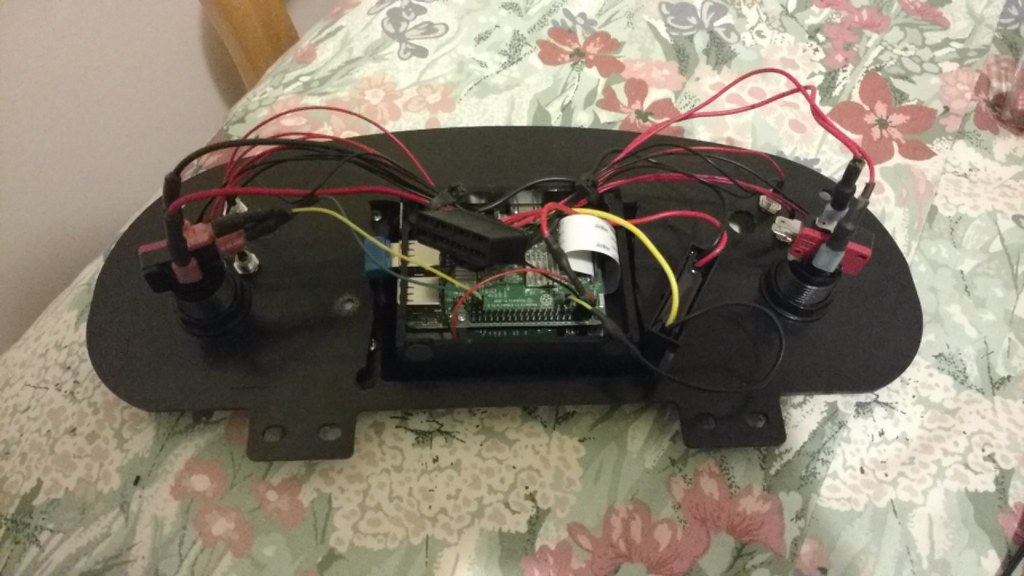

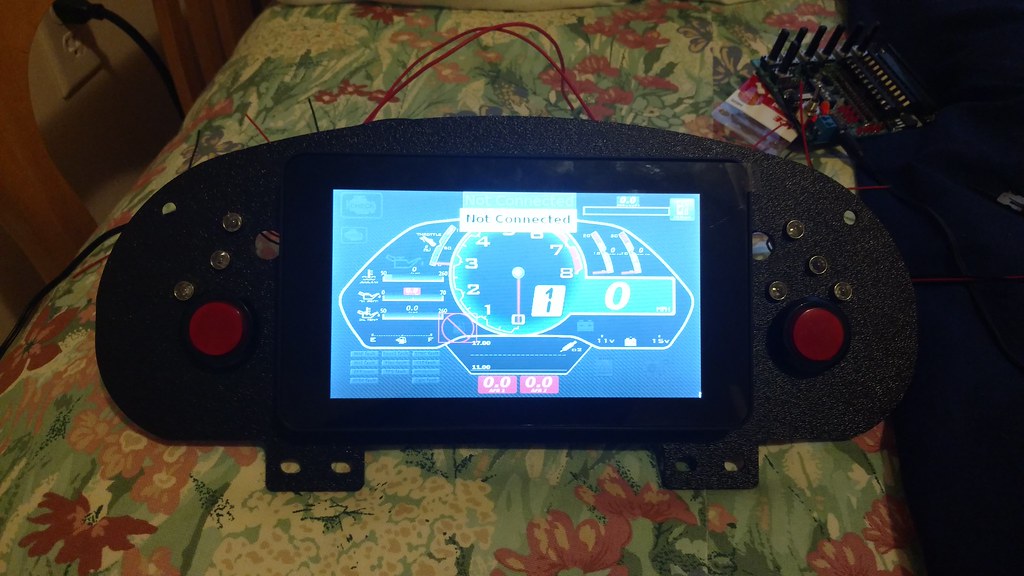

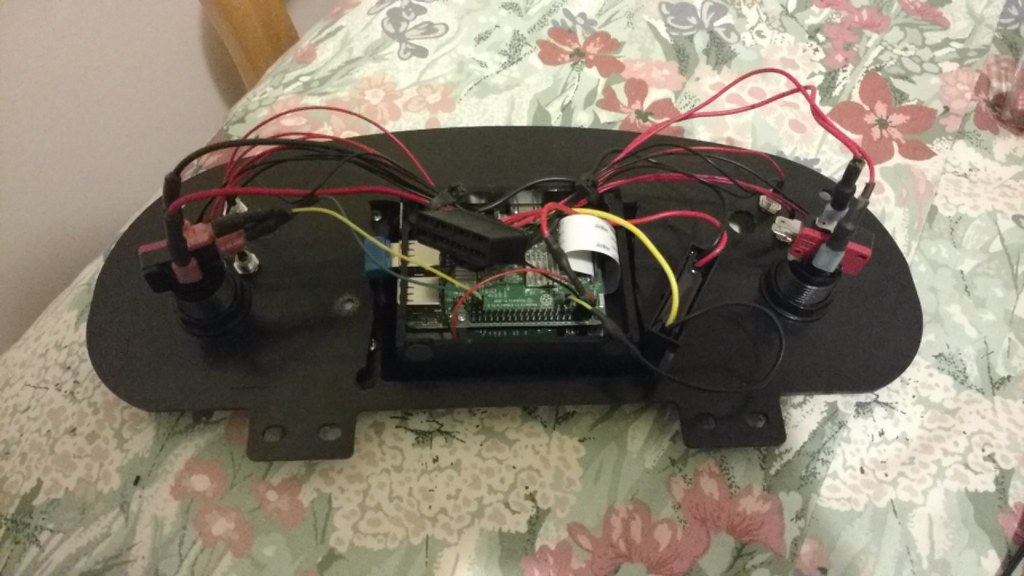

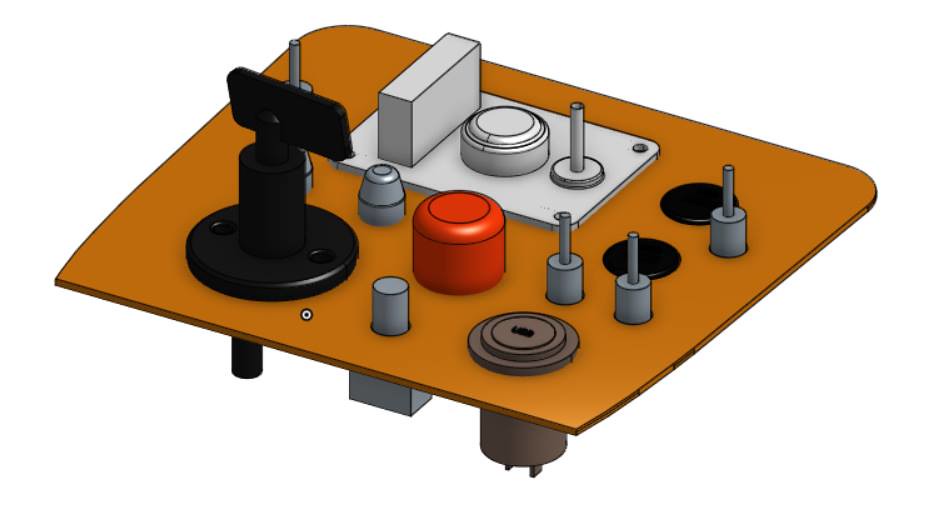

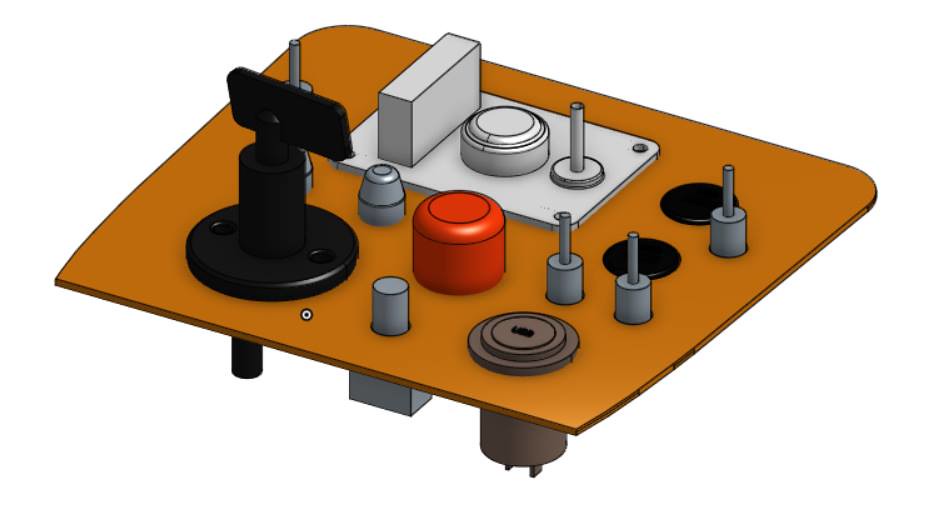

Buttoned up the Raspberry Pi dash. It's a Raspberry Pi 3, 7" Raspberry touchscreen, mounted in a case that's mounted to my cluster plate. It's running Raspbian Jessie and autostarts TunerStudio on startup. I've seen OBDII reading software, so this isn't just for Megasquirt.

It's powered by a 12-5V 3A regulator from Mausberry Circuits, and has a command that when a GPIO pin is triggered to ground, it commands a safe shutdown. There are switch circuits that are intended to have constant power and switched power, but I just kept it simple. I just have to push the big red button on the right side before killing power to the vehicle. The 3 lights in a row on either side (kind of in a row haha) is a sequential tachometer, so it'll illuminate green, yellow, red as RPM's increase. The red light (shown in the second picture) is a red light for coolant temp warning (just a fail safe in case it's not super easy to see the screen). The big red buttons also have integrated lights, these are the turn signal indicators.

All wiring is crimped and heat shrunk (with glue inside), then terminated to an 8 pin Sumitomo conector (from Corsa Technic) to make it removable from one connector, without pulling any components.

IMG_20170129_172255982 by Adam Watson, on Flickr

IMG_20170129_172227193 by Adam Watson, on Flickr

Snapchat-1522824405 by Adam Watson, on Flickr

It's powered by a 12-5V 3A regulator from Mausberry Circuits, and has a command that when a GPIO pin is triggered to ground, it commands a safe shutdown. There are switch circuits that are intended to have constant power and switched power, but I just kept it simple. I just have to push the big red button on the right side before killing power to the vehicle. The 3 lights in a row on either side (kind of in a row haha) is a sequential tachometer, so it'll illuminate green, yellow, red as RPM's increase. The red light (shown in the second picture) is a red light for coolant temp warning (just a fail safe in case it's not super easy to see the screen). The big red buttons also have integrated lights, these are the turn signal indicators.

All wiring is crimped and heat shrunk (with glue inside), then terminated to an 8 pin Sumitomo conector (from Corsa Technic) to make it removable from one connector, without pulling any components.

IMG_20170129_172255982 by Adam Watson, on Flickr

IMG_20170129_172227193 by Adam Watson, on Flickr

Snapchat-1522824405 by Adam Watson, on Flickr

#30

V8 Miata Follower

Thread Starter

Absolutely! I may get the ECU running on the bench soon to get video of it working, otherwise it'll be several months until it's actually driving. I've got a ton of interest so far in this, so I'll definitely be keeping everyone updated on how it works. I can also put together a little how-to with links and everything. I may be making another setup just like this for a friend, so if it goes smooth I may consider branching out and making them for others who are interested.

#31

V8 Miata Follower

Thread Starter

I'm trying to finish up all projects that I can do indoors. I'm really dreading going out to the garage in the cold... I made a little sub-harness for the power window switches that I'm relocating to the center stack area. It took a lot longer than it probably should've.. Everything that may get taken out as an assembly is getting connectors.

IMG_20170130_215548920 by Adam Watson, on Flickr

IMG_20170130_215548920 by Adam Watson, on Flickr

IMG_20170130_215548920 by Adam Watson, on Flickr

IMG_20170130_215548920 by Adam Watson, on Flickr

#32

V8 Miata Follower

Thread Starter

I updated a final version of my center stack switch panel, and brought it to life! The top left and right switches are the power window switches from the previous post. Fighter pilot looking switch is a blower motor switch, followed by the engine start button next to it, then the Accusump activation switch. The 2 USB ports at the top right are just bulkheads, and one will be used for Megasquirt communication. The 2 switches just below are a failsafe for my PWM circuits. I'm PWM'ing both the cooling fan and fuel pump, and if the PWM circuit fails, this will command 100% duty cycle. Button at the bottom is for datalog. The circular E-stop kills power to the ECU and fuel pump. The battery kill is obviously a main kill switch. The two ***** just above control traction control and launch control.

16387010_10155160362883115_8319110369273778173_n by Adam Watson, on Flickr

16387010_10155160362883115_8319110369273778173_n by Adam Watson, on Flickr

16487711_10155160357548115_7887680035998261698_o by Adam Watson, on Flickr

16487711_10155160357548115_7887680035998261698_o by Adam Watson, on Flickr

16387010_10155160362883115_8319110369273778173_n by Adam Watson, on Flickr

16387010_10155160362883115_8319110369273778173_n by Adam Watson, on Flickr 16487711_10155160357548115_7887680035998261698_o by Adam Watson, on Flickr

16487711_10155160357548115_7887680035998261698_o by Adam Watson, on Flickr

#34

V8 Miata Follower

Thread Starter

I remade the Raspberry dash plate, it looks 100 times better now. It's a lot heavier than it should be, since I made it on a waterjet. Since it's all 2D machining, and the screen is 0.333" thick, the plate I made it out of had to be 0.375" thick, with a 0.08" backing plate to mount the screen. At least the 0.375" thick piece is HDPE so it's not too heavy, it's actually nice that it feels much sturdier than the Advanced Autosports panel I was previously using. The easy method would be making it on a router so I could take out material. Either way, I'm super happy with how it turned out.

The following users liked this post:

pj_mcgarvey (02-07-2017)

The following users liked this post:

acedeuce802 (02-08-2017)

#36

V8 Miata Follower

Thread Starter

Test fit the headers with sub-frame. Seems clearances are all good to go. Next step is wrapping the headers. It took a long time to make the decision between coating and wrapping, but I decided that a combination of simplicity of being able to do it myself, cost, and effectiveness, as well as the fact that I really like the look of wrapped headers made it worth it. The trade off is possible corrosion of the headers, but I don't think that'll be an issue with the Kooks stainless. This car will see very minimal rain, so they should stay mostly dry, other than moisture obviously.

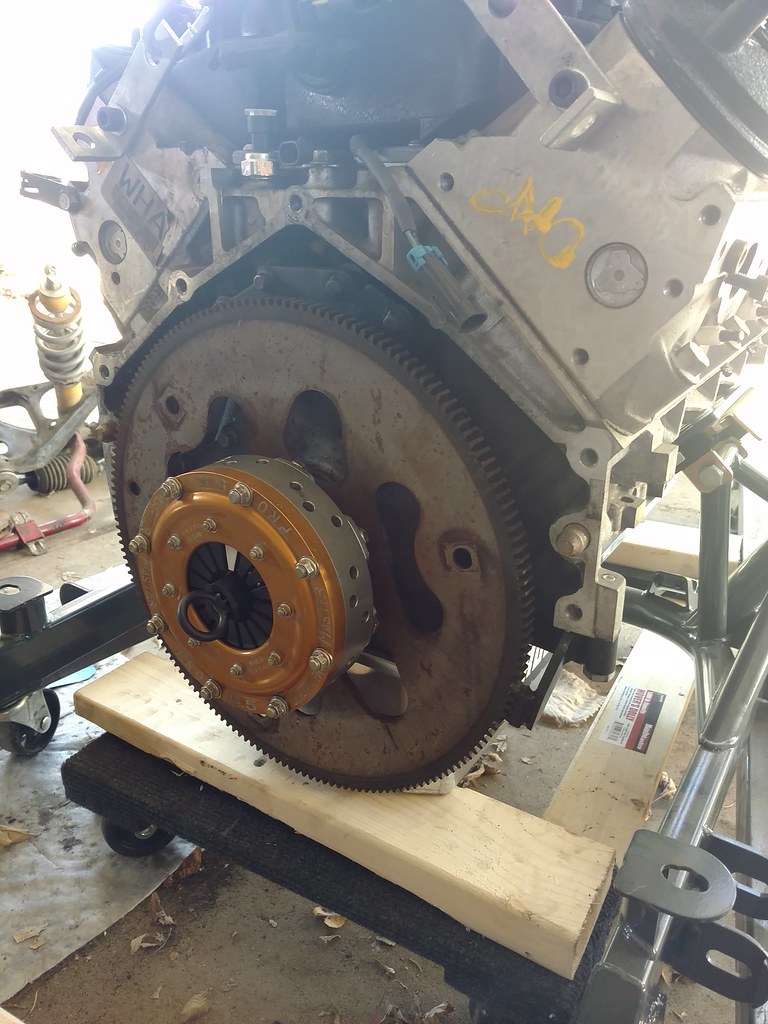

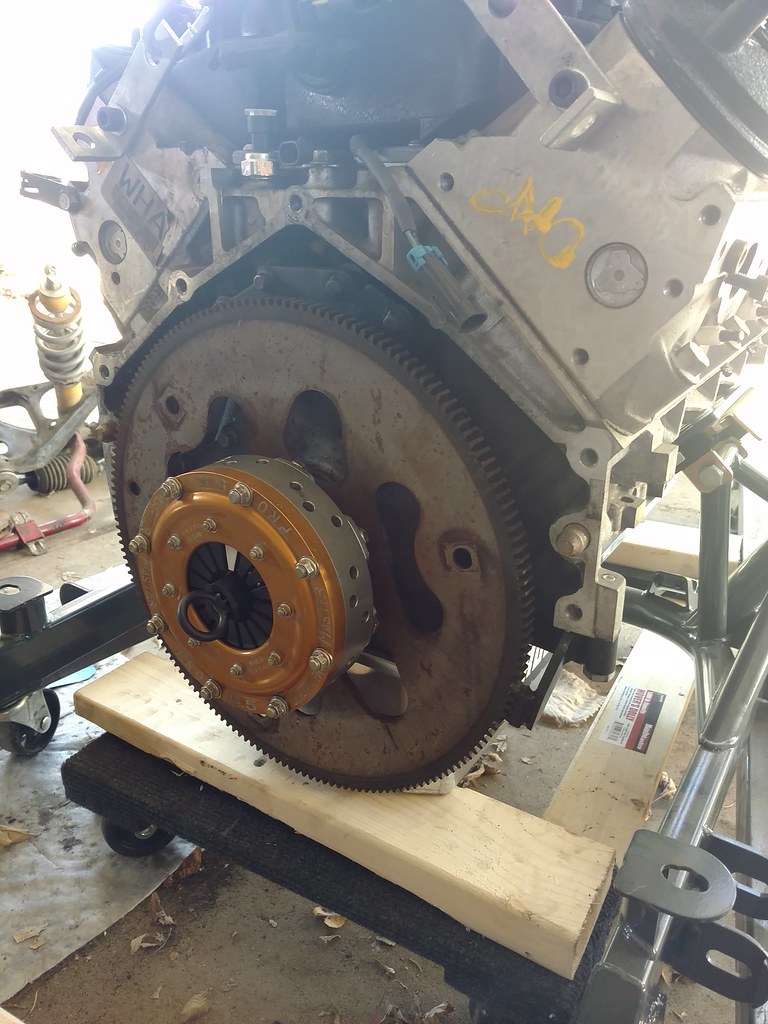

Got the clutch and flex plate mounted up! The release bearing is also shimmed to set the clearance between the bearing and the clutch forks. I made a mistake when making my adapter plate for the release bearing, so the fluid ports aren't pointed at the openings on the bellhousing, so now I need 90 degree fittings to get the lines to fit in the bellhousing. Those should be in on Tuesday so I can get the trans on the motor, and get everything installed back in the car to continue accessory mock up and wiring.

Got the clutch and flex plate mounted up! The release bearing is also shimmed to set the clearance between the bearing and the clutch forks. I made a mistake when making my adapter plate for the release bearing, so the fluid ports aren't pointed at the openings on the bellhousing, so now I need 90 degree fittings to get the lines to fit in the bellhousing. Those should be in on Tuesday so I can get the trans on the motor, and get everything installed back in the car to continue accessory mock up and wiring.

#38

V8 Miata Follower

Thread Starter

Thanks, yeah they are V8r. I know that SupaDupaSteve is using them, maybe some more. I think there are a few others using them on the V8 Miatas Facebook page.

Supa's test fit photos are here: https://www.v8miata.net/general-moto...ld-1889/page7/

Supa's test fit photos are here: https://www.v8miata.net/general-moto...ld-1889/page7/

#39

V8 Miata Fanatic

I simply had no idea how small a diameter your clutch assembly really is until the above photo!

Please update this build thread with more and more pics and comments. This V8Miata will simply be one of the more outrageous ones when completed.

Ace wrote on page one: "This may be quite over board, but we'll see. I picked up a Quartermaster Pro 5.5 triple disc clutch for pretty cheap! This thing is crazy light, 13.5 lbs including clutch and flywheel but not including the auto flex plate it bolts to."

Please update this build thread with more and more pics and comments. This V8Miata will simply be one of the more outrageous ones when completed.

Ace wrote on page one: "This may be quite over board, but we'll see. I picked up a Quartermaster Pro 5.5 triple disc clutch for pretty cheap! This thing is crazy light, 13.5 lbs including clutch and flywheel but not including the auto flex plate it bolts to."

#40

V8 Miata Follower

Thread Starter

Yeah, it's really amazing to see it bolted to the flex plate, the difference in size is incredible!

Will do! Now that it's starting to warm up in Michigan there will be a lot more steady progress.

Fun fact, that clutch came off of one of the 1st gen Cadillac CTS-V Pirelli World Challenge cars, and the release bearing is off of a C5r racecar!

Will do! Now that it's starting to warm up in Michigan there will be a lot more steady progress.

Fun fact, that clutch came off of one of the 1st gen Cadillac CTS-V Pirelli World Challenge cars, and the release bearing is off of a C5r racecar!

The following users liked this post:

ToySnakePMC (02-21-2017)

#41

V8 Miata Follower

Thread Starter

Some small updates. I got the new fuel pump in. I went with a DW300. NB's aren't plug and play for these fuel pumps, so I had to wire in the new connector. I looked all over for how to do the wiring, and came to the conclusion that the wires don't need insulation, just to keep them from touching each other since gasoline is an insulator so it's not conductive. Most heat shrink is not fuel compatible. So I used crimp connections near the fuel pump connector, slid a rubber fuel hose over the splice, then used the factory twisty cord stuff to keep the rubber hose in place, and insulate the ground wire. Before anyone notices, I did remove the regulator that's still on there in the picture.

Next up, I welded EGT bungs on the 7th and 8th runners. I'm only using 2 since I'm not trying to do any fancy individual cylinder trims or anything, just monitoring for safety. 7th and 8th runners should be the hottest, and it's probably good to at least see both banks. It's been a few years since I've welded stainless, not too shabby! Makes me excited to make the exhaust.

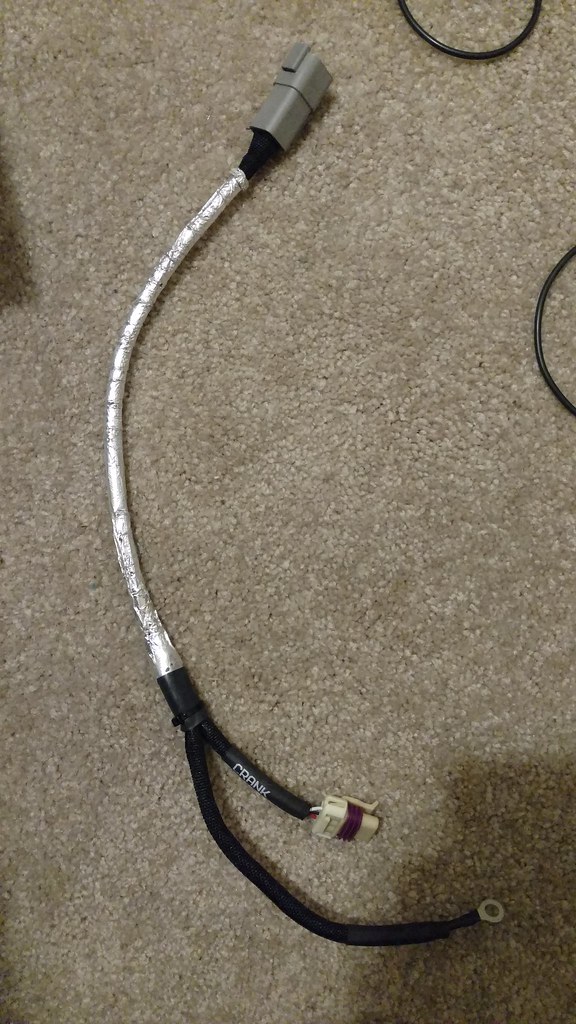

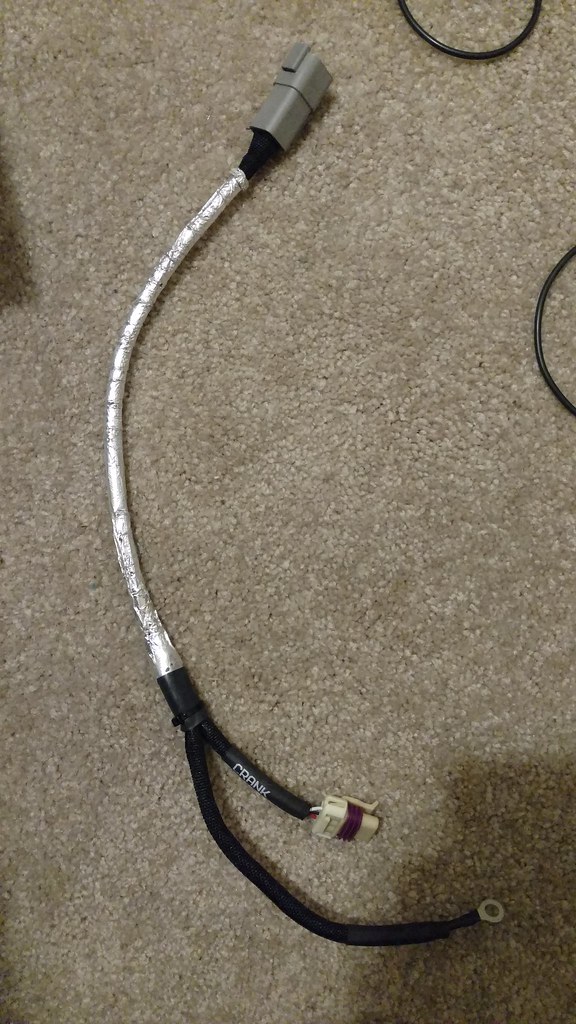

I've always thought it was weird that the crank sensor needs plugged in before the starter can be installed. This would make for an annoying install, that you need to get the motor close to the engine bay, plug in the sensor, install the starter, then install the headers. So I put a Deutsch connector in-line that will sit right at the top of the passenger head. These are solid contacts crimped with a proper DMC crimp tool (the joys of working for a racing company, having nice tools to use!). The crank sensor wire is a shielded wire, so I had to put a pin and socket on the shielding to pass that through the connector.

Next up, I welded EGT bungs on the 7th and 8th runners. I'm only using 2 since I'm not trying to do any fancy individual cylinder trims or anything, just monitoring for safety. 7th and 8th runners should be the hottest, and it's probably good to at least see both banks. It's been a few years since I've welded stainless, not too shabby! Makes me excited to make the exhaust.

I've always thought it was weird that the crank sensor needs plugged in before the starter can be installed. This would make for an annoying install, that you need to get the motor close to the engine bay, plug in the sensor, install the starter, then install the headers. So I put a Deutsch connector in-line that will sit right at the top of the passenger head. These are solid contacts crimped with a proper DMC crimp tool (the joys of working for a racing company, having nice tools to use!). The crank sensor wire is a shielded wire, so I had to put a pin and socket on the shielding to pass that through the connector.

#42

V8 Miata Enthusiast

Some small updates. I got the new fuel pump in. I went with a DW300. NB's aren't plug and play for these fuel pumps, so I had to wire in the new connector. I looked all over for how to do the wiring, and came to the conclusion that the wires don't need insulation, just to keep them from touching each other since gasoline is an insulator so it's not conductive. Most heat shrink is not fuel compatible. So I used crimp connections near the fuel pump connector, slid a rubber fuel hose over the splice, then used the factory twisty cord stuff to keep the rubber hose in place, and insulate the ground wire.

#43

V8 Miata Follower

Thread Starter

I dug into the scrap pile and found enough bends to make an X-pipe today, even though I won't be using it for a while.

Got the new starter in, it's a truck starter. AC Delco 337-1119 and also ordered the 2 bolts, AC Delco 11610787. This starter is 6.5" from flange to back of the starter, so it has about an inch of clearance to the V8roadsters long tubes. There is only one area where clearance is down to about 0.020", but that's on a little sheet metal piece that houses one of the screws to hold the starter case on. I can grind that down a bit, there's extra meat. You can also see the crank sensor and starter wire in place.

Got the new starter in, it's a truck starter. AC Delco 337-1119 and also ordered the 2 bolts, AC Delco 11610787. This starter is 6.5" from flange to back of the starter, so it has about an inch of clearance to the V8roadsters long tubes. There is only one area where clearance is down to about 0.020", but that's on a little sheet metal piece that houses one of the screws to hold the starter case on. I can grind that down a bit, there's extra meat. You can also see the crank sensor and starter wire in place.

#44

V8 Miata Follower

Thread Starter

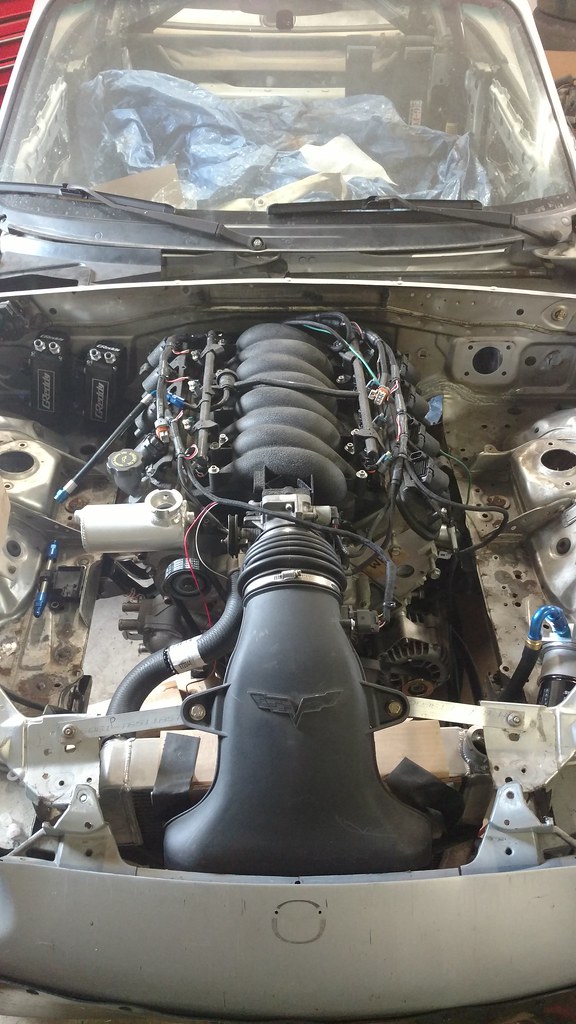

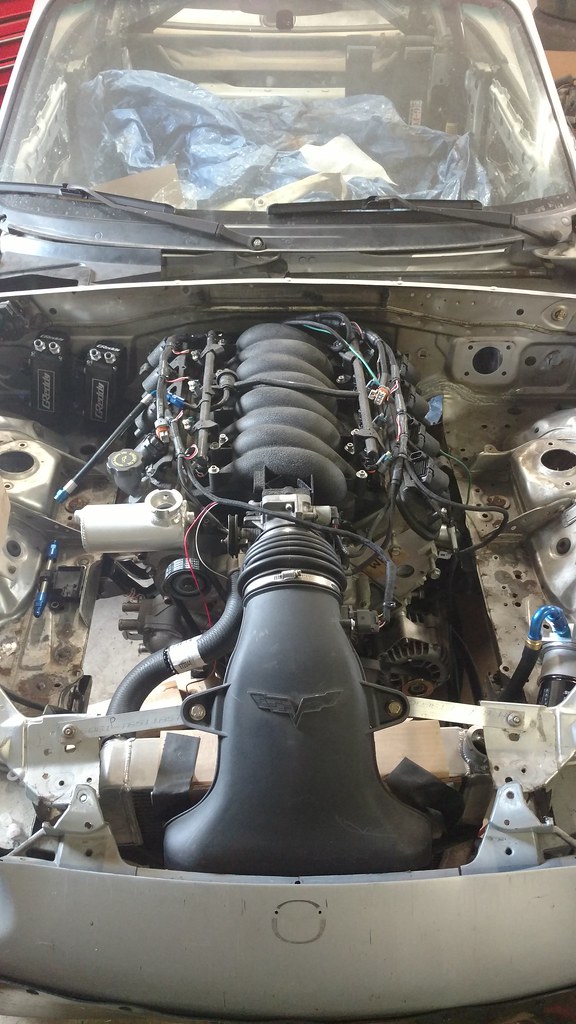

Not as much progress this weekend as I'd like, but it's starting to look like an engine bay at least. I got the engine back in with the headers on so I can start fitting up oil hoses, filter mount, oil cooler, flex fuel sensor, catch cans, etc.

Be warned, V8roadsters long tube headers and the Flyin' Miata LS1 oil pan with remote oil filter mounts are not a good combo. There is VERY little room to work with, and I'm hoping I can find a combination of hose ends that keeps them away from the headers and above the lowest point of the car. I think I have a solution and will post when I have these lines made.

The oil cooler is going to mount perpendicular to the radiator, just to the right of the LS7 intake. I'll have fender vents at some point to expel pressure that builds up in the wheel wells, to help the pressure differential over the oil cooler, but there's going to be a huge high pressure zone in front of it anyway. Then the filter will mount near where it is in the picture, but the filter will hang inboard of the frame rail.

I've also got some coolant hoses that work. I picked up hoses E71317 and E72044. These match the diameters of the radiator and LS1 ports. My Sirocco radiator has 1.5" and 1.75" ports whereas the LS1 has 1.25" and 1.5" ports, and these hoses have the appropriate reduction built in. I'm just taking the 90 degree bends from the ends of each of these hoses, and using a coupler in between.

Also got the Diyautotune plug and play harness test fit on there, and started wiring up the LS7 MAF, since the harness doesn't use MAF and uses an LS1 IAT.

Be warned, V8roadsters long tube headers and the Flyin' Miata LS1 oil pan with remote oil filter mounts are not a good combo. There is VERY little room to work with, and I'm hoping I can find a combination of hose ends that keeps them away from the headers and above the lowest point of the car. I think I have a solution and will post when I have these lines made.

The oil cooler is going to mount perpendicular to the radiator, just to the right of the LS7 intake. I'll have fender vents at some point to expel pressure that builds up in the wheel wells, to help the pressure differential over the oil cooler, but there's going to be a huge high pressure zone in front of it anyway. Then the filter will mount near where it is in the picture, but the filter will hang inboard of the frame rail.

I've also got some coolant hoses that work. I picked up hoses E71317 and E72044. These match the diameters of the radiator and LS1 ports. My Sirocco radiator has 1.5" and 1.75" ports whereas the LS1 has 1.25" and 1.5" ports, and these hoses have the appropriate reduction built in. I'm just taking the 90 degree bends from the ends of each of these hoses, and using a coupler in between.

Also got the Diyautotune plug and play harness test fit on there, and started wiring up the LS7 MAF, since the harness doesn't use MAF and uses an LS1 IAT.

#45

V8 Miata Protégé

I have a couple questions.

Do you know the part number or anything for that air intake boot? My intake did not come with one. Also, for your little expansion tank, where will that tie into the cooling system?

Do you know the part number or anything for that air intake boot? My intake did not come with one. Also, for your little expansion tank, where will that tie into the cooling system?

#46

V8 Miata Follower

Thread Starter

I do not know about that boot. I got lucky and found an LS7 intake on eBay for $70 shipped, and it came with the boot and new filter.

I'm running without a heater core, so the expansion tank will run to the large port on the water pump.

I'm running without a heater core, so the expansion tank will run to the large port on the water pump.

#48

V8 Miata Protégé

From my research it seems to be that the heater lines should be looped if no heater core is present. So if I have an expansion tank made I can put a fitting for each size on there and it should be ok. And thanks for the part #

#49

V8 Miata Follower

Thread Starter

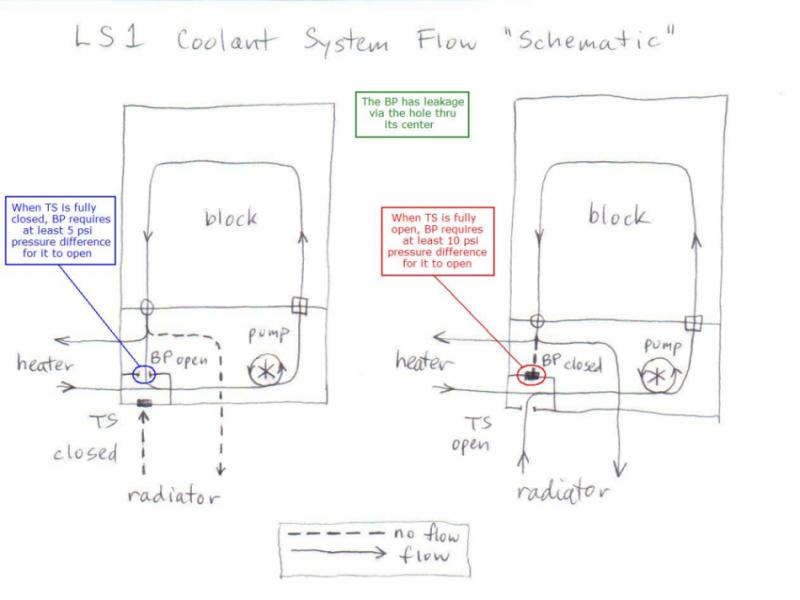

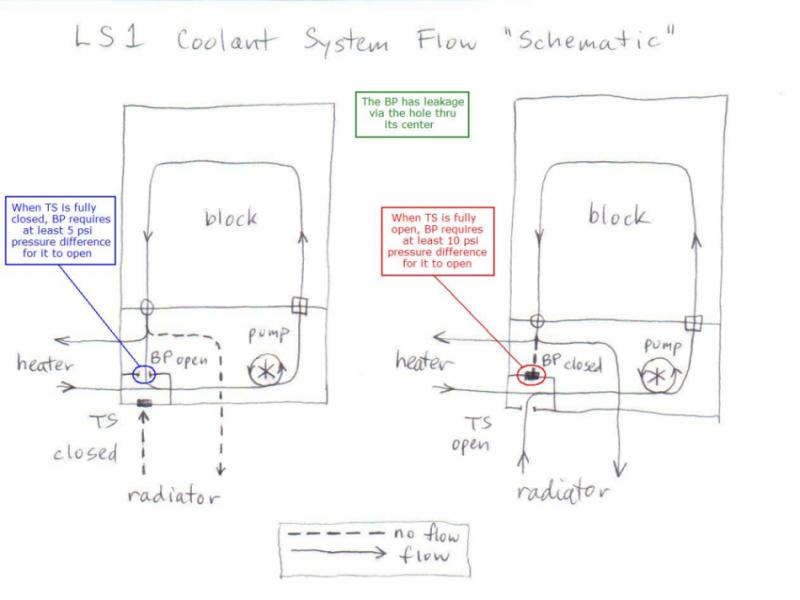

Thanks for the heads up. I'm looking into it now, and am seeing varying advice. Some are adamant that the ports need looped, and some say there's no need for flow. It seems the safe way is definitely to loop them, or run both to the expansion tank.

My take on what I've read is that the portion of the thermostat that actually actuates the plunger is on the "cold" side of the thermostat (the rectangle area at the bottom left corner of the below photo). If there is no flow to this volume, the thermostat will never see the high temperature water at this location and therefore won't actuate as soon as it should. Instead of looping the lines, I may drill a few holes between the engine side and the bypass, since I was hoping to run my coolant pressure transducer off the heater core outlet plug.

My take on what I've read is that the portion of the thermostat that actually actuates the plunger is on the "cold" side of the thermostat (the rectangle area at the bottom left corner of the below photo). If there is no flow to this volume, the thermostat will never see the high temperature water at this location and therefore won't actuate as soon as it should. Instead of looping the lines, I may drill a few holes between the engine side and the bypass, since I was hoping to run my coolant pressure transducer off the heater core outlet plug.

#50

V8 Miata Follower

Thread Starter

Working my way through the fuel system. I've got the regulator mounted, supply and return from tank to regulator, and just need one fitting to come in to finish the main supply line. I'm putting the flex fuel sensor on the supply side since it can take a while for the fuel in tank to reach the injectors when the regulator is at the tank. These sensors can support well over 500 hp on the supply side, since it is 3/8" straight through. This is mounted to the shock tower, then I have a Jiffy-Tite dry-break on the short line that runs from the flex fuel sensor to the fuel rail.

The oil filter is mounted and lines run from the oil pan to the filter housing. Now I just need to mount the oil cooler and run the lines from the sandwich plate to the cooler.

To show why there's tight space with the FM oil pan and long tube headers, here's a shot of the lines. There is just barely enough room between the lines and the pan/block, and just barely enough between the lines and header. The header will be wrapped, and the lines will be covered in heat insulation, so I'm not concerned about that.

The oil filter is mounted and lines run from the oil pan to the filter housing. Now I just need to mount the oil cooler and run the lines from the sandwich plate to the cooler.

To show why there's tight space with the FM oil pan and long tube headers, here's a shot of the lines. There is just barely enough room between the lines and the pan/block, and just barely enough between the lines and header. The header will be wrapped, and the lines will be covered in heat insulation, so I'm not concerned about that.